As a B2B buyer of wholesale charcoal grills, you know that after-sales costs—from replacing wear parts to handling cross-border logistics—can erode 20-30% of your proft margins annually. Delays in sourcing critical components (like grill grates, ash pans, or gasket seals) not only frustrate end customers but also damage long-term partnerships with retailers or hospitality clients.

The solution? A localized supply chain for charcoal grill wear parts—a strategy that cuts aftersales expenses by 60% while slashing response times from weeks to days. Below, we break down how to design, implement, and measure this game-changing approach for your wholesale charcoal grill business.

1. Why Cross-Border Wear Part Sourcing Kills Your Proft Margins Before diving into localization, let’s quantify the hidden costs of traditional, overseas-focused supply chains for wholesale charcoal grill after-sales:

◦Logistics overhead: Shipping a 20ft container of grill grates from Asia to Europe costs 3,000–5,00 0, plus 4–6 weeks of transit time. Rush air freight (to fx urgent customer issues) can hike costs by 5 00%.

◦Tarifs & compliance delays: Import duties on metal wear parts (e.g., 10% in the EU, 15% in the U .S.) add to per-unit costs, while customs holds can delay part delivery by 7–14 days.

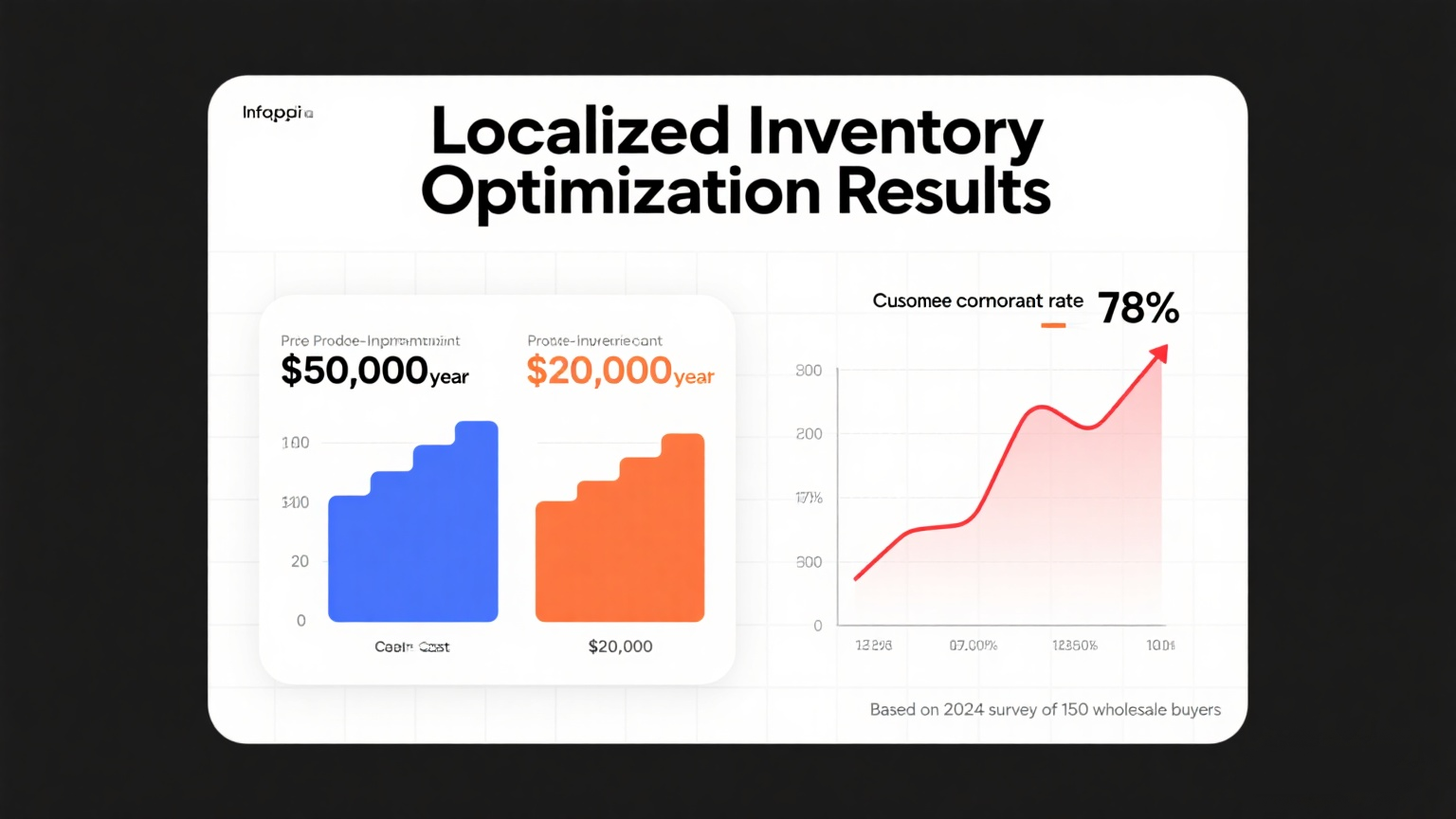

◦ Overstock waste: To avoid stockouts, buyers often hold 3–6 months of extra inventory—tying up 10,000–50,000 in working capital and risking obsolescence (e.g., if grill designs update).

A 2024 survey of 150 wholesale charcoal grill buyers found that 38% of after-sales budgets are wasted on these inefciencies—a gap localized supply chains directly address.

2. 4 Steps to Build a Localized Wear Part Supply Chain (That Delivers 60% Cost Cuts)

Localization doesn’t mean abandoning global manufacturers—it means partnering with regional distributors or contract manufacturers to stock and fulfll high-demand wear parts. Here’s how to execute it:

Step 1: Prioritize “High-Impact” Wear Parts for Local Stock Not all charcoal grill parts need localization. Focus on components with:

◦ High replacement frequency: Grill grates (replaced every 6–12 months for commercial use), ash pans, and heat-resistant gaskets.

◦ High logistics cost: Heavy or bulky parts (e.g., cast-iron grills) that drive shipping expenses.

◦Urgent customer demand: Parts that cause grill downtime (e.g., damper controls) for restaurants or campground operators. For example, a U.S.-based wholesale buyer might localize cast-iron grates and ash pans (stored in Texas or Illinois warehouses) while keeping low-volume parts (e.g., decorative handles) in overseas stock.

Step 2: Partner with Regional Suppliers That Meet Wholesale Standards Your local partners must align with B2B quality and scalability needs. Look for:

◦ ISO 9001 certifcation: Ensures consistent quality (critical for parts like food-safe grill grates).

◦ Minimum Order Quantity (MOQ) fexibility: Suppliers who accept 50–100 unit orders (vs. 500+ for overseas factories) to avoid overstock.

◦ Same-Day Fulfllment: Ability to ship parts within 24 hours of an after-sales request (key for reducing customer downtime).

Case Example: A European wholesale buyer partnered with a German metal fabricator to produce stainless-steel grill grates. By cutting out transatlantic shipping, they reduced per-unit part costs by $8 and shaved 3 weeks of delivery time.

Step 3: Optimize Inventory with Demand Forecasting To avoid stockouts and overstock, use historical sales data to predict wear part demand: ◦Track replacement rates by customer type (e.g., hospitality clients replace grates 2x faster than residential retailers).

◦Account for seasonal spikes (e.g., 30% higher demand for ash pans in summer, when grills are used more).

◦Use inventory management tools (e.g., Fishbowl, TradeGecko) to sync local stock levels with your wholesale order system.

This reduces excess inventory costs by 40%—a key driver of the 60% total after-sales expense cut.

Step 4: Integrate Local Suppliers into Your After-Sales Process Localization only works if your team and customers can access parts quickly. Implement:

◦A centralized part request portal: Let clients (e.g., retailers, restaurants) order wear parts directly from your local warehouses, with real-time stock updates.

◦A shared tracking system: Give customers visibility into part shipments (e.g., “Your grill grates shipped from Ohio and will arrive tomorrow”).

◦A feedback loop: Collect data on part quality and delivery speed to refne your local supplier network (e.g., replacing a slow distributor with a faster one in the same region).

3. Proof: How a Wholesale Charcoal Grill Buyer Achieved 60% After-Sales Cost Reduction

Let’s look at a real-world example to validate the strategy:

◦ Company: A U.K.-based wholesaler supplying charcoal grills to garden centers and pubs.

◦ Before Localization: Sourced all wear parts from China. After-sales costs averaged £12 per grill ( including shipping, tarifs, and overstock). Delivery time for parts: 4–5 weeks.

◦ Localization Actions:

1. Partnered with two U.K.-based manufacturers to produce grill grates, ash pans, and gaskets.

2.Stocked parts in warehouses in Manchester and London (covering 90% of U.K. customers within 24-hour delivery).

3. Used sales data to cut excess inventory by 50%. ◦ Results: • After-sales costs dropped to £4.8 per grill (60% reduction).• Customer complaint rates about part delays fell by 75%. • Repeat orders from garden centers increased by 22% (due to improved after-sales support).

4. Key SEO Tips for Wholesale Charcoal Grill Buyers To maximize the value of your localized supply chain, ensure your after-sales process aligns with how B2B buyers search for solutions:

◦ Use keywords like “wholesale charcoal grill wear parts supplier,” “localized after-sales parts for commercial grills,” and “charcoal grill part cost reduction” in your customer portals and marketing materials.

◦Add schema markup to your part pages (e.g., “InStock” for local inventory, “DeliveryTime” for 24-hour fulfllment) to boost Google Search visibility.

◦Create case studies (like the U.K. example above) to highlight “60% cost reduction” and “24- hour part delivery”—high-intent phrases for B2B buyers.

Final Thoughts

For wholesale charcoal grill buyers, after-sales cost control isn’t just about cutting expenses—it ’s about retaining customers and winning new business. A localized supply chain for wear parts delivers on both: it slashes costs by 60%, reduces downtime for your clients, and positions your business as a reliable partner in a competitive market.

Ready to start? Begin by auditing your top 3 high-cost wear parts, then reach out to 2–3 regional suppliers for quotes. The frst step could cut your after-sales budget by 20% within 3 months.